The expansion joint manufactured by Cauchos Vikingo® is a device that allows movement between two part of structure. It works either if the movements are due to dilation, temperature, ambient or external agents such as vehicles traveling on the structure. Our joints allow a fluency in rolling movements and support movements due to dynamic loads of the structure.

Types of Joints

Small Displacement Joints

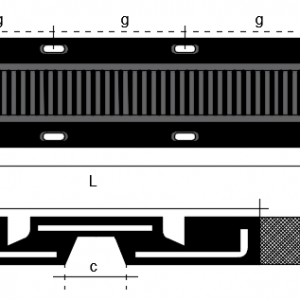

Small Displacement joints are devices that enable the relative movements of lesser magnitude between two parts of a structure. It works either if the movements are due to temperature, ambient or external agents such as vehicular traffic.

Products of Small Displacement Joints

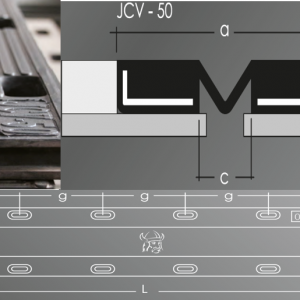

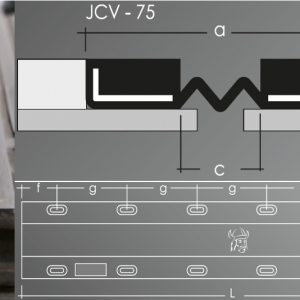

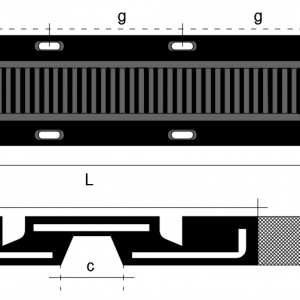

Medium sized Displacement Joints

Medium sized displacement joints are made 100% of neoprene. They are devices that enable the relative movements of medium magnitude between two parts of a structure. They are resistant to extreme environmental conditions and are designed for heavier traffic.

Products of Medium sized Displacement Joints

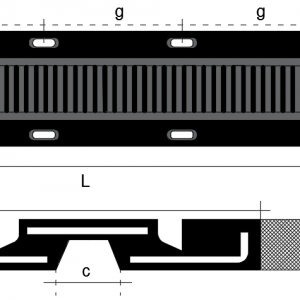

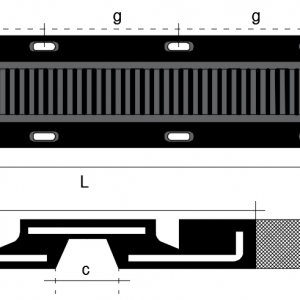

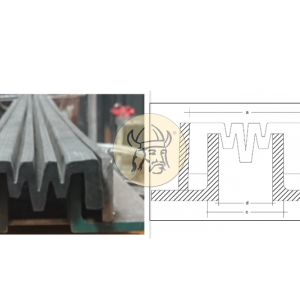

Big Displacement Joints

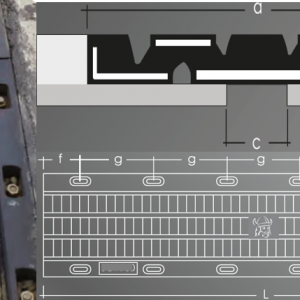

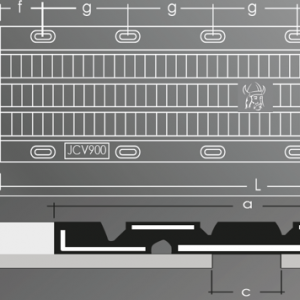

Big displacement joints are devices allowing movements up to 330 mm between two parts of a structure. They are resistant to extreme environmental conditions and are designed for heavy traffic.

Products of Big Displacement Joints

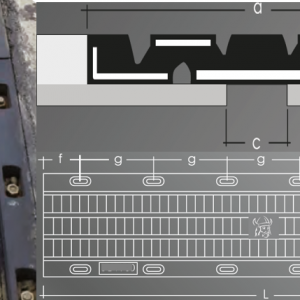

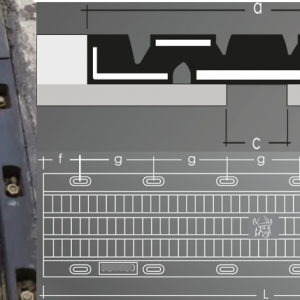

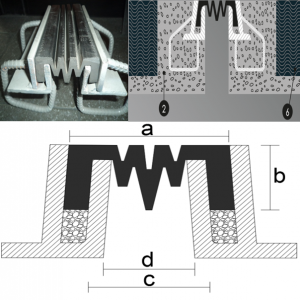

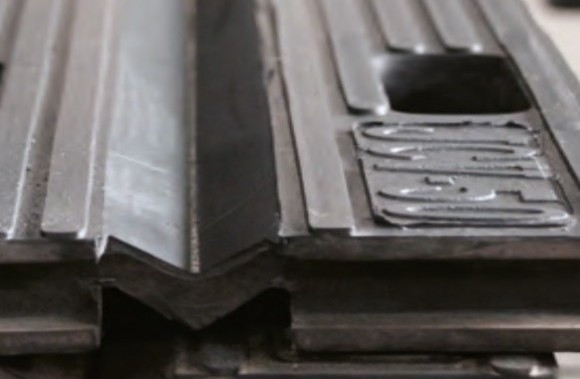

Seismic Joints

Special seismic joints are devices for large movements consisting a metal plate and rubber in a for of an accordion. These speacial joints can be symmetrical or asymmetrical, depending on the needs.

They are functional and have a high absorption capacity of multidirectional movement. As a general rule, seismic joints are considered those whose movement capacity is at least 25% of the joint width in the horizontal axis.

The seismic joints can support normal traffic and extreme environmental conditions.

Products of Seismic Joints

Technical Specifications of Neoprene

Test |

Value |

Units |

Testing method |

| IR spectroscopy | Neoprene | FT-IR spectrum | ASTM D3677-10 |

| Indentation hardness | 65±5* | Shore A | ASTM D 2240 |

| Tensile strength | >190 | Kgs /cm² | ASTM D 412 |

| Elongation at breakage | 45 a 65 ≥425 56 a 65 ≥350 66 a 75 ≥300 |

% | ASTM D 412 |

| Rubber-steel adherence | ≥11.8 | N/mm | ASTM D429 Method B |

| Tearing resistance | ≥32 | kNm | ASTM D624 (Molde C) |

| Low temperature resistance | -30 | ºC | ASTM D 1329 |

| Ozone resistance | no cracks | ASTM D 1149 (D518 method A) 100 ppm O (100 hours a 38ºC) | |

| Deformation remnant | 35 | % Maximum | ASTM D 395 Method B (22 hours a 100º C) |

| Thermal aging | 15 -15 -40 |

± Shore A % Initial load % initial elongation |

ASTM D573 For hot air (70 hours 100º C) |

| Construction method for bridge supports | AASHTO M251 | ||

Technical Specifications of A36 Steel

| Elastic limit (MPA) | ≥ 250 |

| Tensile strength (MPA) | ≥ 390 |

| Minimum elongation 200 mm (%) | ≥ 20 |

| Minimum elongation 50 mm (%) | ≥ 23 |

Types of Installation

For the installation of expansion joints, trained personnel are employed depending on the work to be performed. Critical care must be taken as the proper functioning and durability of the device depends on this step. The installation process which is detailed below, is done in a standardized way in order to reduce costs, time and obtain optimal results according to the required specifications.

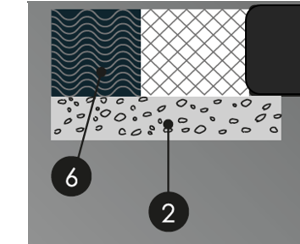

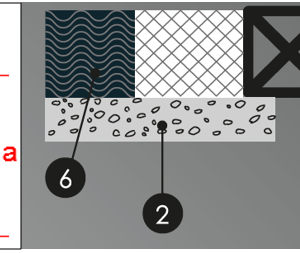

This process begins with receipt of the requirements specified by the customer. The type of installation is either direct, with grout or elastomeric, as detailed above:

No transitional space and the board is placed directly to the asphalt, durability is low (0-2 years)

The transition space is filled with high strengt mortar grout to protect the expansion joint. Durability is medium (1-3 years).

The mortar which is ready to use, is composed of specially graded cement sand and properly dosed additives to control volume changes in cement hydration.

The transition space is filled by a rubber-based mortar, tough and flexible enough to confine the joint and maintain its good performance. Its durability is high (2-5 years).

Characteristics

The installation plan is done with staff designated for this activity.

After determining the logistics for the installation, a prior analysis of the conditions under which the installation will be performed is done.

The terrain on which the joint is placed is thoroughly prepared. Since it is designed to be installed in a specific order, any changes to it can result in premature damage of the joint, malfunctions, unevenness in the asphalt layer among others. Then it proceeds to the installation of the board itself, following the established procedure.

Projects

See catalog