The Elastomeric POT bearings are used to control the interaction of loads and movements between the beams and piles that support a structure. Main use is on bridges. In bridges they are part of the structural assembly, helping normal displacement and to partially absorb the energy of thermal expansion of the beams.

POT type bearings manufactured by Cauchos Vikingo® show excellent resistance to aging.

They do not become soft or hard at high temperatures and remain their elasticity and usability through prestressing during long periods of time. We use Neoprene for our POT devices.

Bearing Types

Each POT bearing fulfills a particular function based on structural calculations. We can differentiate the following types.

The process begins with a receipt of the requirements specified by the customer. Type of bearing is determinated. They are categorize the following way:

Firm PFV type POT Bearings have zero displacement. Its function is to absorb the horizontal forces from any direction. Its design makes movement between the base and piston is reduced almost to zero.

Used Standards: ASSHTO, ASTM, NEVI-12, ISO9001:2015

The PUV type bearings allow unidirectional movement of the bearing and has the ability to absorb perpendicular horizontal forces. The stainless steel plates ensure smooth sliding on the central guide. The bearings are made of vulcanized high quality neoprene according to the standards ASSHTO, ASTM and Nevi-12.

PVL type bearings facilitate movement in any direction, thus achieving not to absorb any horizontal forces. The lateral displacements are more limited compared to other types of displacement. For not having guides its lower stainless steel plates give movements in any direction. Made of vulcanized high quality neoprene rubber according to standard ASSHTO, ASTM and NEVI-12.

Characteristics

All our bearings are made to measure, based on customer specifications

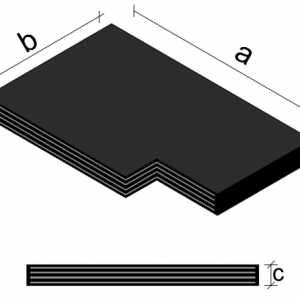

- They are formed of layers of elastomer, steel plates, stainless steel and PTFE depending on the case.

- Vulcanized high quality neoprene rubber according to the standard ASSHTO.

- Inner steel plates ASTM A36.

- NEVI-12 standards

- Made under ISO quality standard 9001:2015

- European standard EN-1337-5

Technical Specifications of Neoprene

Test |

Value |

Units |

Testing Method |

| IR Spectroscopy | Neoprene | FT-IR spectrum | ASTM D3677-10 |

| Indentation Hardness | 50±10* | Shore A | ASTM D 2240 |

| Tensile Strength | >190 | Kgs /cm² | ASTM D 412 |

| Elongation at Break | 45 a 65 ≥425 56 a 65 ≥350 66 a 75 ≥300 |

% | ASTM D 412 |

| Rubber-steel Adherence | ≥11.8 | N/mm | ASTM D429 Method B |

| Tearing Resistance | ≥32 | kNm | ASTM D624 (Mold C) |

| Resistance to Low Temperature | -30 | ºC | ASTM D 1329 |

| Resistance to Ozone | No cracks | ASTM D 1149 (D518 method A) 100 ppm O (100 hours a 38ºC) | |

| Deformation Remnant | 35 | % of maximum | ASTM D 395 Method B (22 hours a 100º C) |

| Thermal Aging | 15 -15 -25 |

± Shore A % Initial charge % Initial elongation |

ASTM D573 For hot air (70 HORAS 100º C) |

| Construction method for bridge bearings | AASHTO M251 | ||

Technical Characteristics of A36 Steel

| Elastic limit (MPA) | ≥ 250 |

| Tensile strength (MPA) | ≥ 390 |

| Minimum elongation 200 mm (%) | ≥ 20 |

| Minimum elongation 50 mm (%) | ≥ 23 |

Technical Characteristics of Astm A240 Steel

| Elastic limit (MPA) | ≥ 340 |

| Tensile strength (MPA) | ≥ 517 |

| Minimum elongation 200 mm (%) | ≥ 30 |

Projects

see catalog